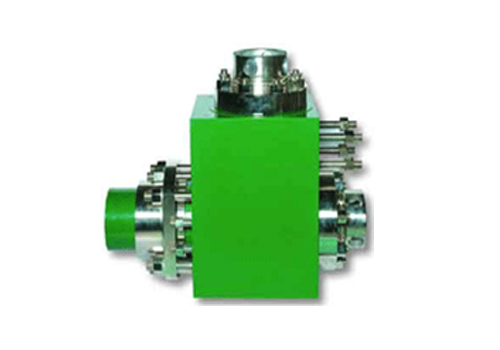

Heat-treated and internally hardened for high durability; available in various materials to meet a wide range of applications; standard one-and/or-two-piece configuration, with designs available for pressure of 5000psi(35.1Mpa), 7500psi(52.7Mpa), and 10000psi(70.3Mpa); discharge connections available on each side; suction connections on each side or front center.

Material is 35CrMoA or 40CrMoNn alloy forged steel. To get better fiber texture, we use electric stove for second forging, or deoridation treatment. It is forged from three directions and the forging ratio is not less than 4.0:1.0.

It cannot have crack, impurity, looseness, overburns, etc. And weld is not allowed. It should be confirming to the stipulation of JB/TQ252-81, and should be checked by gradeⅢ. After quenching the rough module will be rough processed,

then the hull hardness is HB285-330.

Mechanical property: σb ≥850MPa, σs≥670MPa, δ≥5%,ψ≥30%.

The two1:6(1:12) taper hole rolling treatments are checked by ring gage. Its contact area has continuous

distribution on the circumference. The contact area is not less than 75% .The line of intersection of all cylindrical surface of the hull are facetted obtuse angle by hand or grinding wheel ,forming a circumference R≥8.Test pressure

is 49Mpa, keep pressure 1 hour, pressure cannot be reduced. Finished products have crack detection report.

Detailed Product Description

Triplex Fluid End Modules:

Our high strength forged triplex fluid end modules, are made from 4130 or 4135 metal and heat treated to hardness for long wear. The clean exterior finish reflects the superior inside quality.

We furnish all associated items with the modules:

Valve and cylinder head plugs Valve cylinder head threaded rings Valve cylinder head locks

Studs and nuts Duplex Fluid Ends:

We also manufacture duplex fluid end modules to API standards